SS Flanges Manufacturer in Mumbai

Table of Contents

Introduction

JK ENGINEERING WORKS is the Best Ms Flanges Manufacturer in Mumbai, with a family-owned business established in 1996, has built its reputation on the cornerstones of high-quality products, customer satisfaction & superior service. JK ENGINEERING WORKS was formed by well experienced Mr. JAVED KHAN to provide reliable and quality service to the Marine, Petroleum plants, Oil solvent plants, Water Treatment plants, Fertilizers Plant and Mechanical Heavy Industries.

Quality, dependability, and accuracy are critical considerations when choosing parts for mechanical systems and pipes in today’s industrial environment. In many industrial applications, SS flanges are essential for guaranteeing safe connections, leak-proof couplings, and smooth flow. JK ENGINEERING WORKS stands out as a reputable SS Flanges Manufacturer in Mumbai for companies looking for high-quality products in India, providing excellent solutions suited to a variety of industrial needs. Mumbai has become a centre for the production and delivery of premium stainless steel (SS) flanges.

One of the most reputable companies in the sector, JK ENGINEERING WORKS, is a top producer of SS flanges in Mumbai, meeting both customer and industry standards. With decades of experience and a dedication to quality, JK ENGINEERING WORKS offers a variety of flanges appropriate for a range of industrial applications, such as the oil and gas, chemical, water treatment, and power generation industries. We are the best SS Flanges Supplier in Nagpur.

Why Are SS Flanges

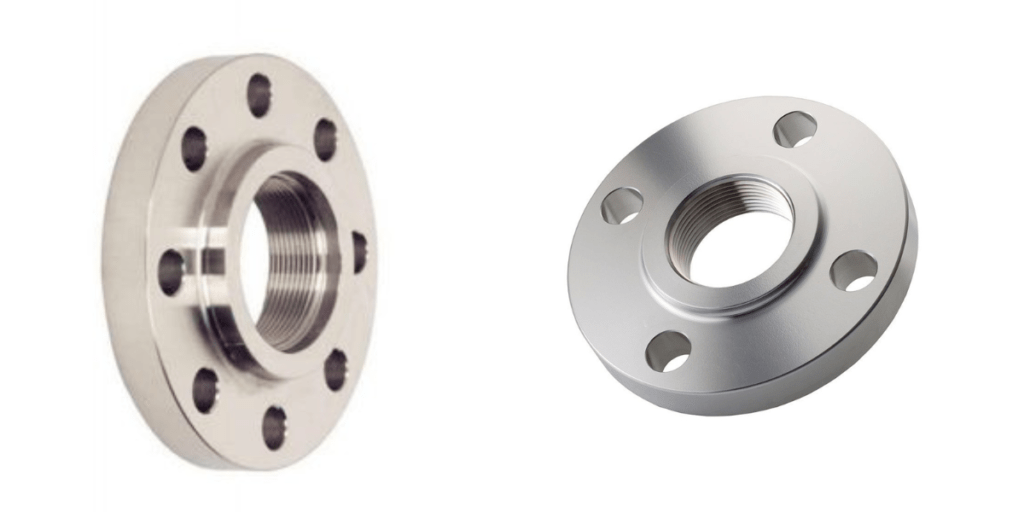

Stainless Steel (SS) Flanges are essential components used to connect pipes, valves, pumps, and other equipment in a piping system. These flanges provide a secure, leak-proof connection, allowing for efficient transportation of liquids, gases, and other substances. Manufactured from high-grade stainless steel, SS flanges are corrosion-resistant, durable, and capable of withstanding high temperatures and pressure, making them ideal for industrial applications. At JK ENGINEERING WORKS, we offer a comprehensive range of SS flanges in various types, sizes, and grades to suit diverse industrial requirements. We are the best SS Flanges Exporter in Aurangabad.

Why Choose JK ENGINEERING WORKS

1. Superior Quality Materials

- A trusted SS flanges manufacturer in Mumbai uses high-grade stainless steel that ensures corrosion resistance, strength, and long-term durability. This guarantees that the flanges can withstand extreme temperatures, pressure, and chemical exposure, making them suitable for diverse industrial applications such as oil & gas, petrochemicals, water treatment, and power plants.

2. Precision Engineering and Compliance

- Top manufacturers employ advanced machining and CNC technology to produce flanges that adhere strictly to international standards like ANSI, DIN, IS, and JIS. Precision engineering ensures proper fitment, leak-proof connections, and operational safety. Compliance with these standards also makes the products reliable for both domestic and export requirements.

3. Wide Range of Products

- A reputable manufacturer in Mumbai offers a comprehensive range of SS flanges, including slip-on, weld neck, blind, threaded, and socket weld flanges. This variety ensures that clients can find flanges suitable for every type of piping system, pressure class, and application, eliminating the need to source from multiple suppliers.

4. Customisation and Flexibility

- Mumbai-based manufacturers often provide customised solutions tailored to specific industrial needs. Whether it’s size, thickness, material grade, or pressure rating, a reliable SS flanges supplier ensures that the product matches your unique requirements. Customisation enhances system efficiency and minimises installation issues.

5. Experienced Technical Support

- Working with a professional SS flanges manufacturer in Mumbai provides access to expert guidance and technical support. Experienced engineers assist in selecting the right flanges, providing installation advice, and troubleshooting operational challenges, ensuring smooth project execution and reduced downtime.

6. Timely Delivery and Competitive Pricing

- Reputed manufacturers understand the importance of on-time delivery and offer flanges at competitive prices without compromising quality. This combination of affordability and reliability helps businesses maintain project schedules and budget efficiency.

7. Trust and Industry Reputation

- Choosing a well-established SS flanges manufacturer in Mumbai means partnering with a company known for consistency, trustworthiness, and excellent customer service. Positive industry reputation and long-term client relationships are strong indicators of a manufacturer’s credibility.

8. Competitive Pricing and Timely Delivery

- Mumbai-based SS flange manufacturers combine quality with cost-efficiency, offering competitive pricing without compromising standards. Efficient production and logistics ensure on-time delivery, even for bulk orders, supporting smooth project execution.

9. Technical Expertise and Support

- Reliable manufacturers offer professional guidance on flange selection, material compatibility, and installation practices. Their technical support helps clients optimize performance, reduce operational risks, and maintain compliance with industry regulations.

10. Experience & Reputation

- Many Mumbai-based SS flange manufacturers have decades of experience supplying to domestic and international markets. Their expertise guarantees products that conform to global standards and meet the expectations of diverse industries.

Applications of SS Flanges

1. Petrochemical & Oil Refining Industry

- In petroleum refineries and petrochemical complexes, piping systems transport volatile and corrosive fluids. SS flanges:

- Withstand high temps and pressure

- Resist sulfide stress cracking

- Ensure leak‑proof integrity

2. Chemical & Pharmaceutical Plants

- Chemical manufacturing often deals with strong acids, alkalis, solvents, and toxic fluids. SS flanges are vital because of:

- Corrosion resistance against aggressive chemicals

- Excellent hygiene compliance

- Cleanable and contamination‑free joints

3. Food & Beverage Industry

- SS flanges are ideal where sanitation is non‑negotiable dairy, breweries, edible oil processing, and sugar mills rely on them due to.

- Non‑toxic, non‑corroding surfaces

- Easy cleaning and sterilisation

- No contamination from rust or residues

4. Power Generation

- Power plants — thermal, nuclear, and renewable — use SS flanges in boiler feed lines, condensate systems, and cooling circuits. The benefits include:

- Resistance to high heat and cyclic stress

- Pressure containment integrity

- Compatibility with steam environments

5. Water Treatment & Desalination

- SS flanges are widely used in municipal and industrial water systems due to:

- High corrosion resistance

- Low maintenance

- Long operational life

6. Shipbuilding & Marine Applications

- Exposure to seawater demands superior anti‑corrosion performance. SS flanges are used in:

- Ballast systems

- Sea water cooling circuits

- Fuel and lubricating oil systems

7. HVAC & Fire Protection Systems

- Flanged connections are common in large HVAC units and fire water mains:

- Allow modular installation

- Provide leak‑tight sealing under pressure

- Support maintenance without system shutdown

Specification Table SS Flanges

| Specification Item | Details |

|---|---|

| Material | Stainless Steel Flanges |

| Manufacturer Location | Mumbai, India |

| Material Grades | SS 304, SS 304L, SS 316, SS 316L, SS 310, SS 321 |

| Standards | ANSI/ASME B16.5, B16.47, B16.48 |

| Types of Flanges | Slip-On, Weld Neck, Blind, Socket Weld, Threaded, Lap Joint |

| Size Range | ½″ to 48″ (Custom sizes on request) |

| Pressure Ratings | Class 150, 300, 600, 900, 1500, 2500 |

| Facing Types | RF (Raised Face), FF (Flat Face), RTJ (Ring Type Joint) |

| End Connections | Welded / Threaded |

| Surface Finish | Polished / Mill Finish |

| Testing & Inspection | PT / UT / PMI / Hydro Test |

| Packaging | Standard Export / Custom |

| Application Areas | Oil & Gas, Petrochemical, Chemical, Marine, Power Plants, Water Treatment |

Benefits of SS Flanges

High-Quality Stainless Steel Products

- Reliable SS flanges manufacturers in Mumbai provide products made from premium-grade stainless steel, ensuring exceptional durability, corrosion resistance, and long-term performance in various industrial applications.

Customised Solutions for Diverse Industries

- Mumbai-based manufacturers offer customised flange solutions to meet the unique requirements of industries such as oil & gas, chemical, petrochemical, water treatment, and power plants. This ensures seamless integration with existing piping systems and machinery.

Compliance with International Standards

- Reputed manufacturers adhere to global standards like ASTM, ASME, DIN, and ISO, guaranteeing flanges that meet stringent quality, safety, and reliability criteria, suitable for high-pressure and high-temperature operations.

Advanced Manufacturing Technology

- Leveraging state-of-the-art production techniques, these manufacturers ensure precision engineering, consistent dimensions, smooth finishes, and superior mechanical properties in every flange, reducing installation issues and maintenance costs.

Cost-Effective and Timely Delivery

- Manufacturers in Mumbai combine competitive pricing with fast production and delivery schedules, providing businesses with a reliable supply chain and minimising downtime in critical operations.

Expert Guidance and Support

- Professional manufacturers provide technical consultation, helping clients select the right flange type, material, and specifications for optimal performance, safety, and compliance.

Wide Range of Products

- From slip-on, weld neck, and socket weld flanges to blind and threaded flanges, manufacturers in Mumbai offer a comprehensive selection, allowing industries to source all their stainless steel flange requirements from a single trusted supplier.

Durability and Long-Term Performance

- SS flanges manufactured with precision and high-quality materials offer excellent resistance to rust, oxidation, and chemical exposure, ensuring longevity and reducing replacement frequency, thereby saving costs over time.

Enhanced Reliability in Critical Applications

- Mumbai’s SS flange manufacturers ensure products capable of withstanding extreme conditions, including high pressure, temperature fluctuations, and corrosive environments, making them ideal for demanding industrial operations.

Strong After-Sales Service

- Reputable manufacturers provide robust after-sales support, including maintenance tips, installation guidance, and prompt resolution of any issues, ensuring a smooth experience from purchase to operation.

Types of SS Flanges

1. Weld Neck Flanges

- Weld neck flanges are ideal for high-pressure applications. They feature a long tapered hub that is welded to the pipe, providing excellent strength and resistance to stress. These flanges are commonly used in the petrochemical, oil, and gas industries.

Key Features:

- High strength

- Suitable for high-pressure systems

- Minimal turbulence in fluid flow

2. Slip-On Flanges

- Slip-on flanges are designed to slip over the pipe and then be welded both inside and outside for better strength. These flanges are easy to install and are suitable for low-pressure applications.

Key Features:

- Easy installation

- Cost-effective

- Suitable for low-pressure pipelines

3. Socket Weld Flanges

- Socket weld flanges are used for small-diameter pipes and provide a leak-proof connection. The pipe is inserted into the flange and welded around the hub, making it ideal for high-pressure applications.

Key Features:

- Strong weld connection

- Leak-proof

- Ideal for high-pressure systems

4. Blind Flanges

- Blind flanges are used to close the end of a piping system. They allow easy access for inspection or future expansion of pipelines.

Key Features:

- Easy maintenance

- Provides complete closure

- High durability

5. Threaded Flanges

- Threaded flanges are connected to pipes with threads without welding. They are suitable for low-pressure applications and provide the advantage of quick assembly and disassembly.

Key Features:

- Quick installation

- No welding required

- Suitable for low-pressure systems

6. Lap Joint Flanges

- Lap joint flanges are used with stub ends and are ideal for systems requiring frequent dismantling. They are commonly used in industries like chemical processing, pharmaceuticals, and food processing.

Key Features:

- Easy dismantling

- Reusable

- Corrosion-resistant

Conclusion

JK Engineering Works is a reliable option for businesses in Mumbai looking for a manufacturer of SS flanges. With premium stainless steel flanges, tailored solutions, affordable prices, and prompt delivery, the business guarantees that every industrial need is satisfied with accuracy and dependability. Selecting JK Engineering Works entails making an investment in high-performance, long-lasting, and safe flanges that lower maintenance costs and improve operational efficiency. We are the SS Flanges Supplier in Solapur.

JK Engineering Works offers the ideal stainless steel flange solutions to satisfy your company’s needs, whether you are in the water treatment, food and beverage, chemical processing, or oil and gas industries. Get the best SS flanges in Mumbai by getting in touch with JK Engineering Works right now to make sure your industrial activities operate smoothly with top-notch pipe connections.