Spectacle Blind Flanges Manufacturer

Introduction

JK ENGINEERING WORKS is the Best Ms Flanges Manufacturer in Mumbai with family-owned business established in 1996, has built its reputation on the cornerstones of high-quality products, customer satisfaction & superior service. JK ENGINEERING WORKS was formed by well experienced Mr. JAVED KHAN to provide reliable and quality service to the Marine, Petroleum plants, Oil solvent plants, Water Treatment plants, Fertilizers Plant and Mechanical Heavy Industries.

In the huge and complex world of industrial pipes, where efficiency, safety, and precise control are crucial, some parts are essential yet sometimes overlooked by the average observer. Spectacle Blind Flanges are one of these unsung heroes. From chemical plants and power generation facilities to oil and gas refineries, these clever devices are crucial to the safe and efficient running of numerous industrial processes.We at JK ENGINEERING WORKS are aware of how crucial each part of your plumbing system is.

Being a top producer of spectacle blind flanges, we take great satisfaction in producing goods that combine sturdy construction, premium components, and painstaking craftsmanship to guarantee the highest standards of performance and safety. We are the best Spectacle Blind Flanges Supplier.

What Exactly Are Spectacle Blind Flanges

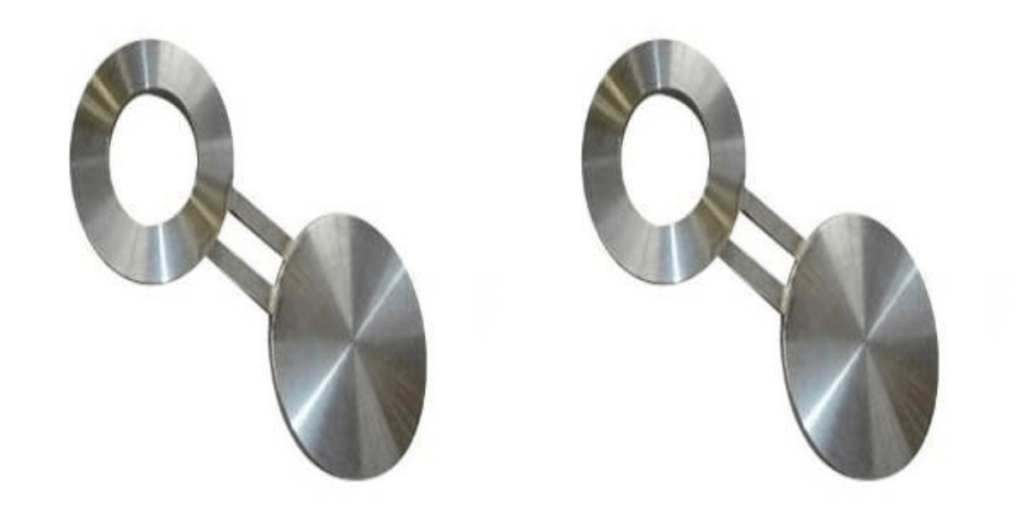

Consider a pair of eyeglasses, or spectacles. The idea for a spectacle blind flange comes from this commonplace item. Like the nose bridge of spectacles, it is made up of two circular discs connected by a little piece. The “open” or “spacer” side of one of these discs has a hole that corresponds to the inner diameter of the pipe, while the “blind” or blank side is solid. We are the best Spectacle Blind Flanges Exporter.

Why Choose JK ENGINEERING WORKS

- Unwavering Dedication to Quality: At the heart of everything we do is quality. The finest quality raw materials, such as different kinds of stainless steel, carbon steel, alloy steel, and special alloys, are used in the production of our spectacle blind flanges and are all obtained from reliable suppliers. Every flange is subjected to stringent quality inspections and testing, including material analysis, mechanical testing, and pressure testing, in accordance with international standards like We give you total piece of mind by including thorough MTCs Material Test Certificates with every order.

- Decades of Expertise and expertise: JK ENGINEERING WORKS has refined its trade over the course of decades of expertise in the engineering and manufacturing sectors. Our staff of highly qualified engineers and technicians is well-versed in industrial applications, production procedures, and flange design. Because of our vast experience, we are able to create spectacle blind flanges that are not only expertly designed but also constructed to function faultlessly in the most trying conditions.

- Advanced Manufacturing Capabilities: We make investments in state-of-the-art machinery and contemporary production plants. Our manufacturing process makes use of cutting-edge equipment and methods to guarantee precise dimensions, excellent surface polish, and constant product quality for all of our flanges. We use best techniques in forging, machining, and heat treatment to produce high-quality products.

- Vast Selection of Materials and Sizes: JK Engineering Works provides a wide selection of spectacle blind flanges in a range of sizes (from 1/2″ to large bore applications), pressure ratings and materials. What we can offer is.

- Adaptation to Your Requirements: We are aware that store-bought remedies aren’t always adequate. When it comes to creating spectacle blind flanges that meet your exact specifications for dimensions, drawings, and materials, JK Engineering Works is an expert. We can effectively manage complicated and specialized requirements because to our adaptable manufacturing method.

- Customer-Centric Approach: Our customers are the center of all we do at JK Engineering Works. We are committed to establishing enduring partnerships founded on dependability, trust, and top-notch customer service. From your initial inquiry to post-delivery support, our committed sales and technical support staff are always available to help. We pledge to deliver on time and communicate clearly at every stage of the procedure.

- Competitive Pricing without Sacrificing Quality: We work hard to provide extremely affordable prices without sacrificing the functionality and quality of our spectacle blind flanges. Our robust supply chain management and effective manufacturing procedures enable us to provide our clients with outstanding value.

- Dependable Supply Chain and Prompt Delivery: JK Engineering Works, situated in India, a manufacturing powerhouse, enjoys the advantages of a strong supply chain network. Our efficient logistics guarantee that your purchases are processed quickly and delivered on time, reducing any possible delays to your operations. We recognize the significance of project timeframes.

- A Partner for Your Success: By selecting JK ENGINEERING WORKS, you’re getting more than just a product you’re also getting a trustworthy partner who is committed to your success. We are dedicated to offering solutions that increase safety, boost productivity, and improve your bottom line because we recognize how important our flanges are to your operations.

Applications of Spectacle Blind Flanges

1. Oil & Gas Industry

- Used in offshore and onshore platforms to isolate sections during inspection or emergencies. They help prevent leakage and maintain pressure integrity.

2. Petrochemical & Chemical Plants

- Where corrosive fluids are handled, our corrosion-resistant spectacle blinds ensure safe plant operations during servicing.

3. Power Plants

- Steam and cooling water lines require regular inspection. Spectacle blinds allow safe line isolation for turbine maintenance.

4. Water Treatment Plants

- Used in inlet and outlet pipelines of filter systems for flow control and service checks.

5. Pharmaceuticals

- Piping systems for fluid processing often need frequent flushing and maintenance, where spectacle blinds prove highly effective.

6. Refineries

- Process pipelines handling high-temperature fluids use spectacle blinds to isolate specific units during turnaround maintenance.

7. Marine Industry

- Engine room systems and ballast lines on ships and submarines require spectacle blinds to ensure safe isolation at sea.

Table of Specifications Spectacle Blind Flanges

| Parameter | Specification |

|---|---|

| Product | Spectacle Blind Flange |

| Size Range | ½” to 48” (DN15 to DN1200) |

| Class Ratings | 150#, 300#, 600#, 900#, 1500#, 2500# |

| Thickness | As per ASME B16.48 or customer drawings |

| Material Grades | CS, SS, Alloy Steel, Duplex, Super Duplex, Inconel, etc. |

| Facing Type | RF (Raised Face), FF (Flat Face), RTJ (Ring Type Joint) |

| Design Standard | ASME B16.48, ASME B16.5, API, DIN, EN |

| Finish | Black Painted, Anti-rust Coating, Galvanized, Pickled & Passivated |

| Inspection & Testing | Hydro Test, PMI, UT, RT, Mechanical Testing |

| Certificate | MTC (EN 10204 3.1 / 3.2), IBR, Third Party Inspection |

| End Connection | Weld Neck / Slip-On / Custom Fabricated |

Benefits of Spectacle Blind Flanges

- Improved Safety: This is possibly the biggest benefit. During maintenance, repairs, or inspections, spectacle blind flanges stop the unintentional flow of hazardous materials by offering a positive, verifiable shut-off. A correctly constructed spectacle blind flange provides a complete physical barrier, significantly lowering the possibility of spills, leaks, and hazardous situations in contrast to a valve, which may leak. Immediate isolation is ensured by the visual confirmation of the “blind” end’s presence.

- Dependable Performance: Even in the most demanding settings, these flanges provide remarkably dependable performance because they are made of sturdy materials and are made to resist high temperatures and pressures. Compared to more intricate isolation systems, they have fewer sources of failure due to their straightforward mechanical design.

- Easy Maintenance and Repair: The spectacle blind flange enables rapid and effective isolation without requiring the complete system to be shut down when a pipeline or piece of equipment needs to be serviced. This makes maintenance processes safer and easier to handle while also minimizing downtime and labor expenses. One component of the system can be worked on while the others remain functional.

- Cost-Effectiveness: Although they need an initial outlay, spectacle blind flanges end up being very economical over time. Over the course of a piping system’s life, its longevity, low maintenance needs, and capacity to stop expensive leaks or accidents add up to substantial savings.

- Versatility: A large range of industries and applications can make use of spectacle blind flanges. To accommodate varied fluid kinds (flammable, poisonous, and corrosive), temperatures, and pressures, they come in a range of sizes, materials, and pressure ratings.

- Operation Ease: Changing the flow status by “swinging” is a simple process that calls for only a few basic tools and a well-defined process. Faster isolation times during planned shutdowns or emergencies are a direct result of this ease of use.

- Regulatory Compliance: Reliable isolation techniques are necessary in many industries due to strict safety laws and requirements. Spectacle blind flanges frequently fulfill or surpass these specifications, assisting businesses in staying in compliance and avoiding fines.

Types of Spectacle Blind Flanges

1. Carbon Steel Spectacle Blind Flanges

- Made using high-quality carbon steel, these flanges are ideal for high-temperature, high-pressure systems. They provide excellent durability and strength.

Applications: Petrochemical industries, power plants, and oil refineries.

2. Stainless Steel Spectacle Blind Flanges

- Manufactured from stainless steel grades like SS 304, SS 316, these flanges are corrosion-resistant and suitable for applications where hygiene and corrosion resistance are critical.

Applications: Pharmaceutical, food processing, water treatment.

3. Alloy Steel Spectacle Blind Flanges

- These flanges are built for exceptional performance in extreme conditions, using materials like Inconel, Monel, Hastelloy, etc.

Applications: High-temperature and corrosive environments.

4. Duplex & Super Duplex Spectacle Blind Flanges

- These types offer superior corrosion resistance, high mechanical strength, and excellent fatigue resistance.

Applications: Marine, offshore and subsea piping systems.

5. Custom Fabricated Spectacle Blinds

- We also offer tailored solutions as per your pipeline size, pressure class, and material specifications.

Applications: Specialized industrial systems requiring custom fitment.

Conclusion

More than just pipe fittings, spectacle blind flanges are essential safety elements that support effective operations and safeguard people and property in some of the most challenging industrial settings on the planet. They are an essential component of contemporary industrial pipes because of their clever “figure-eight” design, which provides unmatched dependability for positive isolation. We are the Best Spectacle Blind Flanges Manufacturer.

You need a partner you can completely rely on when your operations’ safety and the integrity of your pipeline systems are at stake. One of those trustworthy partners is JK Engineering Works. We are a leading manufacturer of spectacle blind flanges because of our unwavering dedication to superior quality, precise manufacturing, vast material expertise, and a genuinely customer-centric approach.