Mild Steel Flanges Manufacturer

Mild Steel Flanges Manufacturer / Mild Steel Flanges Manufacturer in Mumbai / Mild Steel Flanges Manufacturer in India / Mild Steel Flanges Supplier / Mild Steel Flanges Provider in Mumbai /

Introduction

Mild steel (MS) is a type of low-carbon steel that has between 0.05% and 0.25% carbon. Its low carbon content makes it pliable, ductile, and simple to work with, making it an excellent choice for flange fabrication. Mild steel flanges are extensively used in industrial piping systems to connect pipes and prevent leaks.

Flanges serve several functions, including:

- Connecting pipes of varying materials and sizes.

- Allowing for easy cleaning, inspection, and repair.

- Allowing alterations or extensions to pipe systems.

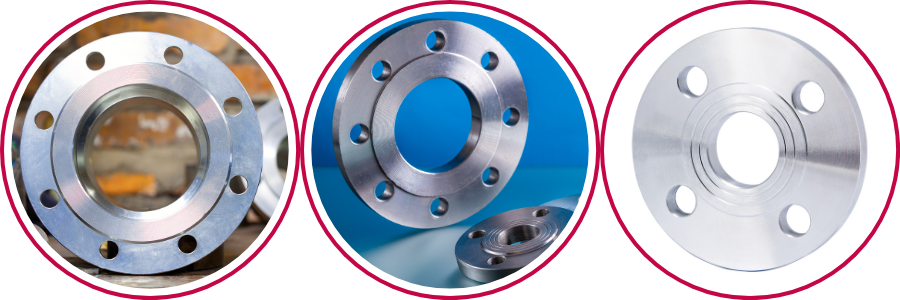

Types of Mild Steel Flanges

Mild Steel Flanges are available in a variety of styles, each tailored for a specific purpose and pressure needs. Here are some of the most popular types:

- a. Slip-On Flanges.

Slip-On Flanges are simple to install and slide onto the pipe before welding. They are appropriate for low-pressure applications and provide an economical option for a variety of industries. - b. Weld Neck Flanges.

These flanges have a long tapered hub, which provides high strength while reducing stress at the flange’s base. Weld Neck Flanges are suited for applications requiring high pressures and temperatures. - c) Blind Flanges

Blind flanges are used to seal the ends of pipes or vessels, stopping fluid passage. They are essential for inspection and maintenance work. - d. Socket Weld Flanges.

- Socket Weld Flanges are used for small-diameter pipes and are welded on the exterior to ensure a sturdy, leak-free connection.

- e. Lap Joint Flanges

- These flanges have stub ends and are suited for applications that require regular dismantling.

- f. Threaded Flanges.

- Threaded flanges contain internal threads that allow them to screw onto pipes without welding, making them ideal for low-pressure applications.

- Orifice flanges are used with orifice plates to measure liquid and gas flow rates.

Applications of Mild Steel Flanges

Mild Steel Flanges find applications in a wide range of industries, including:

- Oil and Gas: Used to carry oil, gas, and other hydrocarbons.

- Petrochemicals: Used in chemical processing industries to connect pipes conveying corrosive chemicals.

- Power Generation: Used in thermal and nuclear power plants.

- Water Treatment: Pipelines in water treatment plants.

- Food and beverage production uses hygienic piping systems.

- HVAC Systems refers to heating, ventilation, and air conditioning systems.

Advantages of Using Mild Steel Flanges

Mild Steel Flanges offer several advantages that make them a preferred choice in various industries:

- Cost-effective: Mild steel is less expensive than stainless steel or alloys.

- MS flanges are highly durable, withstanding moderate pressure and temperature conditions.

- Versatile: Suitable for a variety of applications and situations.

- Easy to fabricate: Mild steel is simple to cut, weld, and shape, making it suitable for unique flange designs.

- Corrosion Resistance: When coated or galvanized, MS flanges are very resistant to rust and corrosion.

Manufacturing Process of Mild Steel Flanges

Mild Steel Flanges are manufactured in multiple stages to guarantee they fulfill industry standards and customer demands. At JK Engineering Works, we use a careful procedure to provide high-quality products:

- a. Material Selection.

Our flanges are made of high-quality mild steel purchased from reliable vendors. - c. Cutting and shaping.

The steel is cut and formed to the appropriate flange design utilizing modern technology and CNC tools. - C. Heat Treatment

Heat treatment improves the mechanical characteristics and strength of the flanges. - D. Machining

Precision machining is used to provide exact dimensions and smooth surfaces. - e.Inspection and testing.

Each flange is subjected to thorough quality inspections, including dimensional inspection, pressure testing, and material analysis. - f. Surface Treatment

- The flanges are coated or galvanized to enhance their corrosion resistance.

- g. Packaging and Delivery

- The finished products are carefully packed and dispatched to customers worldwide.

JK Engineering Works: Mild Steel Flanges Manufacturer

When it comes to Mild Steel Flanges, JK Engineering Works is a prominent manufacturer and supplier. Here are the reasons you should choose us:

- Experience: Over a decade of producing flanges and other piping components.

- Quality: We follow strict quality standards and certifications to ensure that our goods meet or surpass industry specifications.

- Customization: We provide customized solutions to match our clients’ individual needs.

- Competitive Pricing: Our items are competitively priced without sacrificing quality.

- Orders are delivered on time thanks to our solid supply chain and logistical network.

Quality Assurance & Standards Followed by JK Engineering Works

At JK Engineering Works, quality is our top priority. We follow internationally recognized standards, including:

- ISO 9001: Quality Management System.

- ASTM: American Society for Testing and Materials standards.

- The American Society of Mechanical Engineers sets standards for flange diameters and pressure ratings.

- European standards for materials and manufacturing processes.

Customer Testimonials and Case Studies

Here’s what some of our satisfied customers have to say about us:

Mr. Rajesh Kumar, Oil and Gas Company:

“We have been sourcing Mild Steel Flanges from JK Engineering Works for the past five years. Their products are reliable, and their customer service is exceptional.”Ms. Priya Sharma, Water Treatment Plant:

“The customized flanges provided by JK Engineering Works perfectly fit our piping system. We highly recommend them for their quality and timely delivery.”

Conclusion

Finally, Mild Steel Flanges are key components in a variety of industrial applications, providing a low-cost and long-lasting solution for piping systems. JK Engineering Works is a reputable manufacturer you can rely on. With our dedication to quality, personalization, and client satisfaction, we are the appropriate partner for all of your flange needs.