WNRF Flanges Manufacturer

Table of Contents

Introduction

JK ENGINEERING WORKS is the Best Ms Flanges Manufacturer in Mumbai with family-owned business established in 1996, has built its reputation on the cornerstones of high-quality products, customer satisfaction & superior service. JK ENGINEERING WORKS was formed by well experienced Mr. JAVED KHAN to provide reliable and quality service to the Marine, Petroleum plants, Oil solvent plants, Water Treatment plants, Fertilizers Plant and Mechanical Heavy Industries. We are the best WNRF Flanges Supplier.

Flanges are essential in the complex world of industrial pipes, where accuracy and dependability are crucial. The Weld Neck Raised Face (WNRF) flange is distinguished from the wide variety of flanges by its sturdy construction and outstanding functionality. This article highlights the experience of JK Engineering Works, a top WNRF flange producer, while delving into the complexities of WNRF flanges, examining their uses, benefits, and production procedures.

Understanding WNRF Flanges

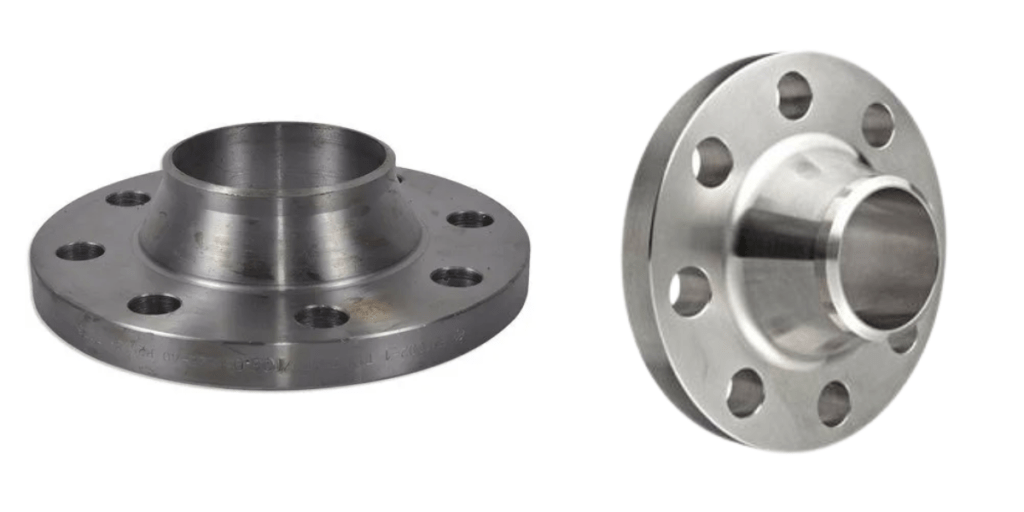

WNRF flanges are essential parts of piping systems made to withstand high temperatures and pressures. They offer a robust and dependable connection between pipes, valves, pumps, and other equipment thanks to its distinctive form, which includes a long, tapering neck and a raised face. We are the best WNRF Flanges Exporter.

Why Choose JK Engineering Works?

- Large Experience: JK Engineering Works has years of experience in the field and the know-how to produce WNRF flanges to the highest standards.

- High-quality Materials: To ensure the longevity and dependability of its flanges, JK Engineering Works exclusively uses the best materials, procured from reliable vendors.

- Modern Manufacturing Facilities: JK Engineering Works has cutting-edge facilities for manufacturing, including sophisticated forging, machining, and testing machinery.

- Tight Quality Control: To guarantee that every flange satisfies the highest requirements for performance and quality, JK Engineering Works keeps an exacting quality control system in place.

- Customization Capabilities: Customers can define their specific material, size, and design needs with JK Engineering Works’ customization possibilities.

- Competitive Pricing: JK Engineering Works offers great value for money with competitive pricing that doesn’t sacrifice quality.

- On-time Delivery: JK Engineering Works is dedicated to providing customers with their flanges when they need them by fulfilling orders on schedule.

- Customer Service: JK Engineering Works offers first-rate customer service, including technical support and timely resolution of client questions.

Applications of WNRF Flanges

- Long-Term Pipeline Integrity: By stopping leaks and guaranteeing the safe carriage of fluids, WNRF flanges in oil and gas pipelines guarantee the pipeline’s long-term integrity. JK Engineering Works contributes to the safety and effectiveness of pipeline operations by offering flanges that satisfy the exacting specifications of these applications.

- Dependable Power Plant Operations: Critical piping systems in power plants that function at high temperatures and pressures require WNRF flanges. JK Engineering Works provides flanges that are resistant to these harsh circumstances, guaranteeing power plants run dependably.

- Sturdy Chemical Processing Systems: WNRF flanges are subjected to hard conditions and corrosive substances in chemical processing facilities. The long-term durability of chemical processing systems is guaranteed by JK Engineering Works’ corrosion-resistant flanges.

- Sustainable Water Infrastructure: WNRF flanges are essential to the safe and effective transportation of water in desalination and water treatment facilities. Flanges from JK Engineering Works satisfy the exacting durability and hygienic standards of water infrastructure.

- Safe Marine Operations: WNRF flanges are utilized in a variety of piping systems on ships and offshore platforms in shipbuilding and marine applications. JK Engineering Works offers flanges that satisfy the exacting specifications of maritime settings, guaranteeing the dependability and safety of marine operations.

Advantages of WNRF Flanges

- Superior Materials: To guarantee the longevity and dependability of our flanges, we only purchase the best raw materials from reputable vendors.

- Strict Quality Control: From material selection to final inspection, we follow strict quality control protocols throughout the whole manufacturing process.

- Experienced Staff: The highest caliber of craftsmanship is guaranteed by the vast experience of our team of knowledgeable engineers and technicians in the production of flanges.

- Customization Capabilities: We provide customization choices to satisfy certain client needs, such as pressure ratings, size, and material selection.

- Competitive Pricing: We work hard to offer our clients outstanding value at competitive prices without sacrificing quality.

- On-Time Delivery: We are dedicated to fulfilling project deadlines and recognize the value of on-time delivery.

- Customer Service: Throughout the purchasing process, we offer thorough customer service, including technical help and direction.

- Broad Product Offering: In addition to being a top manufacturer of WNRF flanges, we also make a variety of other flanges and pipe parts.

- Comprehensive Industry Knowledge: We guarantee that our goods fulfill the strictest quality and safety standards since we have a thorough awareness of industry standards and best practices.

- Long-Term Client connections: By offering top-notch goods and services, we place a high priority on establishing long-term client connections.

Benefits of WNRF Flanges

- Enhanced Reliability: Our premium WNRF flanges guarantee dependable and leak-proof connections, reducing maintenance expenses and downtime.

- Enhanced Safety: Your plumbing systems are safer thanks to our sturdy flanges, which offer exceptional structural strength.

- Enhanced Efficiency: Our precisely designed flanges help to lower pressure drop and increase flow efficiency.

- Decreased Operational Costs: Our long-lasting flanges require less upkeep and replacement, which lowers operating expenses over time.

- Peace of Mind: You can rest easy knowing that you are collaborating with a reliable partner thanks to our dedication to quality and client satisfaction.

- Custom Solutions: We may provide solutions specifically tailored to your requirements, which will boost the project’s effectiveness.

- Consistent Quality: We make sure that every one of our items is of the highest caliber.

- Technical Assistance: We offer knowledgeable technical assistance to assist you in selecting the appropriate flanges for your use.

- Industry Knowledge: With years of experience in the field, our team of professionals can offer you insightful advice.

- Robust Supply Chain: Our robust supply chain guarantees that we can promptly and effectively fulfill your expectations.

- Decreased Project Delays: We assist you in preventing project delays with our prompt delivery and effective production.

- Increased Product Life: Compared to inferior flanges, our superior version will last longer.

- Decreased Risk: We reduce risk by adhering to industry certifications and norms.

- Enhanced Profitability: Our flanges can assist you in increasing profitability by lowering operating expenses and enhancing efficiency.

Types of WNRF Flanges

- WNRF Flanges made of carbon steel are frequently utilized in general-purpose applications where corrosion is not a major issue. They are reasonably priced and have outstanding strength.

- WNRF Flanges made of stainless steel: These flanges are perfect for corrosive settings, like those found in food and chemical processing. They are very durable and resistant to corrosion. 304, 316, and 316L stainless steel grades are frequently used.

- Alloy Steel WNRF Flanges: These flanges are utilized in refineries and power plants, which are high-temperature and high-pressure environments. They are stronger and more resistant to heat.

- Duplex and Super Duplex WNRF Flanges: These are utilized in extremely demanding applications, like offshore oil and gas, and provide extremely high strength and corrosion resistance.

- The most popular kind of WNRF flanges are made of carbon steel and have outstanding strength and weldability. They can be used for a variety of purposes.

- WNRF flanges made of stainless steel: These flanges are perfect for applications involving corrosive fluids or environments because they offer exceptional corrosion resistance.

- High-temperature and high-pressure applications are the focus of alloy steel WNRF flanges, which provide increased strength and creep resistance.

- Duplex and Super Duplex Steel WNRF Flanges: These provide outstanding resistance to pitting and crevice corrosion and are utilized in extremely corrosive conditions.

Conclusion

WNRF flanges are reliable connectors that guarantee the smooth movement of essential resources in the complex dance of industrial pipes. In challenging applications, its durability, versatility, and leak-proof design are essential. By selecting a WNRF Flanges Manufacturer, you’re investing in the durability and integrity of your entire system rather than just buying a component.JK Engineering Works exemplifies the values of dependability and quality. Our dedication to quality is the cornerstone upon which we construct each flange, not merely a catchphrase. We take every precaution to guarantee that our goods meet and beyond industry standards, from the careful execution of our manufacturing procedures to the selection of quality materials. We are the best Weld Neck Flanges Manufacturer.